Welding Table Specs and Features:

| Overall Tabletop Size: | 1500mm x 1000mm x 100mm (59.05" x 39.37" x 3.93") |

| Borehole: | Ø 16mm (0.629") |

| Welding Table Series: | Professional Extreme 8.7 Series |

| Welding Table Material Thickness: | Approx. 11.5 – 13mm (0.45" - 0.51") |

| Welding Table Material Type and Finish: | Hardened Tool Steel, Plasma Nitrided and BAR-Coated Table |

| Table Surface Hardness: | 450-850 Vickers |

| Official Siegmund Welding Table Part No.: | 4-160035.X7D |

| Maximum Weight Load: | 2000 kg. / 4409 lbs. (Based on Even Distribution) |

| Approximate Table Weight: | 615 lbs. / 279 kg. |

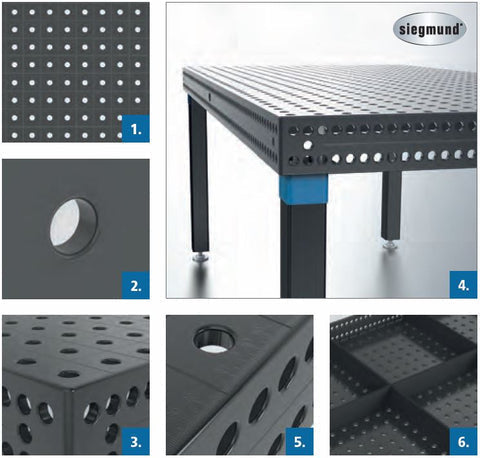

| Boreholes on the Surface: | 50x50mm Grid (1.96"x1.96") |

| Boreholes Radius: | 2mm (0.078") |

| Radius on Table Edges and Corners: | 3mm (0.118") / 6mm (0.236") |

| Height of Table Side: | 100mm (3.93") |

| Borehole Spacing on Table Side: | 25mm (0.98") |

| Metric Scaling: | On the surface |

| Construction: | Reinforced with ribbing |

Siegmund Welding Tables are the Hardest, Most Durable and Extraordinarily Flat Welding Tables Available in the World.

The hardened X7 Steel (the 8.7 Series), is specially made for Siegmund in Germany. This steel is of a considerably higher hardness grade compared to 98% of the welding tables in the market. The only thing harder is our 8.7 series table are our Siegmund 8.8 Series Welding Tables. With the Series 8.7 Siegmund Welding tables, the top plate achieves a hardness of 850 Vickers after the Plasma Nitration and the BAR-Treatment. The higher hardness also helps maintain the flatness of the welding table.

Available Leg Style Variants

The System 16 Welding Table Series was created with Heavy Duty Applications in Mind.

All System 16 Professional Extreme tables feature the latest upgrades in aesthetics, versatility, and durability.

Our Double Hardened Tables are constructed from through hardened steel before undergoing a Plasma Nitride treatment to provide you with a table of superior quality and performance.